- Our products and services

Manufacturing Capabilities

At Mala, manufacturing is where visionary design meets disciplined execution. Our vertically integrated facilities unite advanced materials science, precision automation, and Industry 4.0 analytics to turn bold concepts into market-ready realities—fast. From rapid-prototype runs to full-scale production, we engineer every step for flawless quality, cost efficiency, and sustainability, empowering clients to launch breakthrough products with confidence and speed.

- Injection Molding

- Blow Molding

- Compression Molding

- Secondary Process

let our plastic be part of your business.

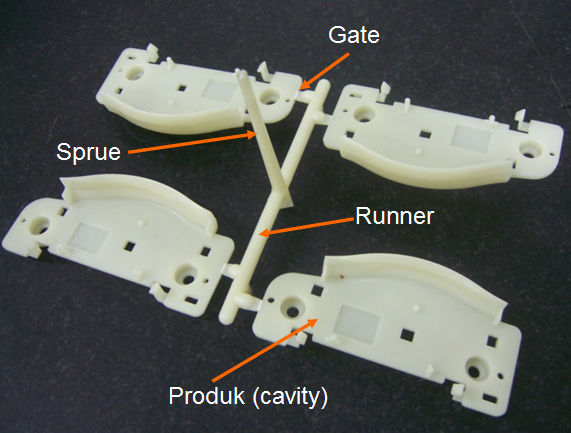

Injection Molding

Malaplast specializes in high-precision, cost-effective injection molding across diverse industries. With 160 machines (15–650 tons) — including fast-cycle, electric, hydraulic, and vertical models — we deliver consistent quality and flexible production.

Our specialized capabilities include:

- High-precision gear molding

- Insert molding

- Optical lens molding

- Thermoset injection molding

| Sector | Part | Material & Highlights |

|---|---|---|

| Consumer Electronics | Wireless-charger cradle housing. | PC-ABS blend, UV-stable, silk-screened logo molded in |

| Automotive | Under-hood cable grommet | 30 % GF nylon, withstands 150 °C and engine-bay chemicals |

| Medical Device | Single-use insulin-pen cap | Medical-grade PP, ISO 13485 clean-room molded, 100 % vision-inspected |

| Home Appliance | Dishwasher spray arm | Talc-filled PP for stiffness, brass insert over-molded for leak-free swivel |

| Personal-Care Packaging | Flip-top shampoo cap | HDPE with in-mold labeling; 48-cavity family mold, 6-second cycle |

Blow Molding

Malaplast has provided high-quality plastic packaging via blow molding since 1971. Operating 28 machines, we produce packaging from 5ml to 30 liters using Extrusion Blow Molding and Injection Stretch Blow Molding. We offer a one-stop solution, from design to full-scale production, serving industries such as food, lubricants, agriculture, chemicals, household & personal care, and pharmaceuticals.

| Sector | Part | Material & Highlights |

|---|---|---|

| Beverage | Water bottle | PET, clear, light |

| Automotive | Fuel tank | HDPE, seamless, tough |

| Personal-Care | Shampoo bottle | PP, built-in handle, colorful |

| Industrial | Chemical drum | HDPE, 200 L, stackable |

| Medical | IV fluid bag | PVC, flexible, sterile |

Compression Molding

Malaplast, Thailand’s first melamine tableware producer and a leading manufacturer, offers high-quality, internationally certified melamine products as an OEM for global clients. Meeting stringent food safety standards (TISI certified), we provide plain, decorative, glazed, and two-tone melamine. Our manufacturing includes 31 compression molding machines (40-500 tons) with various molding technologies, along with pellet preparation, finishing workstations, and ultrasonic welding for complete solutions.

| Sector | Part | Material & Highlights |

|---|---|---|

| Automotive | Brake-pad backing | Phenolic resin, heat-proof |

| Aerospace | Panel core | Carbon/epoxy, high-stiff |

| Electrical | Switchgear insulator. | GF-epoxy, arc-safe |

| Cookware | Fry-pan handle | Bakelite, stay-cool |

| Sports | Helmet shell | SMC fiber, impact-tough |